Study on Additive Manufacturing in automotive industry published

Ampower releases a new study on Additive Manufacturing in automotive industry. The study provides a deep insight on production of metal components by additive technology for sports cars.

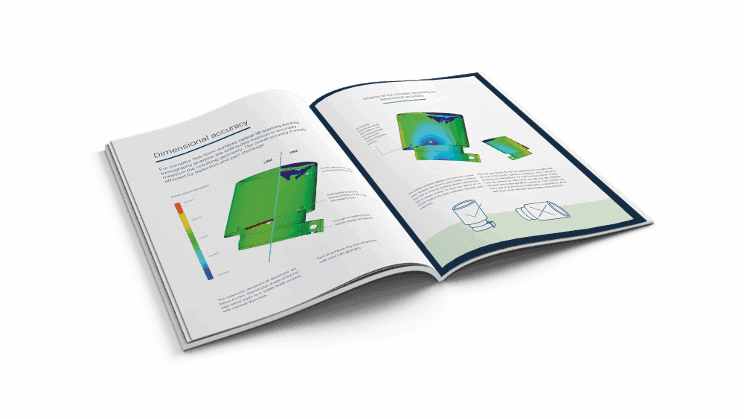

Hamburg – The consultancy Ampower has published a technology study on Additive Manufacturing of high-performance automotive components. The analysis focuses on the production of an exhaust tail pipe blend of a super sports car. In addition to the design optimization, all necessary production steps up to the ready-to-install component are described. Between the individual production steps, the component is examined for different quality criteria. An x-ray analysis is used to determine the dimensional accuracy as well as identification of residual powder. Besides the widely known Laser Beam Melting, the study also considers Electron Beam Melting.

The study reveals that Laser Beam Melting has distinct advantages over Electron Beam Melting for the investigated application. This is in particular due to the requirements of the surface quality. By means of vibratory grinding and polishing, a surface roughness Ra of less than 0.1 μm is achieved in the case of the Laser Beam Melting component. In addition, the use of multi-laser machines makes the production of this component cheaper than Electron Beam Melting.

The sports car manufacturer anticipates that Additive Manufacturing will shorten the lead time, i.e. the time from the digital data set to the finished component. Conventional tail pipe blends are manufactured by means of deep drawing tools, which can result in lead times of several months to a year. In contrast, Additive Manufacturing allows production within a few weeks until the ready-to-install component. In the course of ever shorter development cycles, valuable time can be saved. Due to the low number of sports cars, the process also becomes cheaper.

The 30-page study is available for download at www.am-power.de/insights or can be requested as a hardcopy. It is the second issue of the Ampower Insights series. In the first study, Ampower gave a detailed insight into the cost structure of Additive Manufacturing of metal components.

339 words, 2214 characters

About Ampower

Consultancy Ampower (www.am-power.de) specializes in industrial Additive Manufacturing. The company was founded in 2017 by technology experts Dr. Maximilian Munsch, Matthias Schmidt-Lehr and Dr. Eric Wycisk. Ampower advises their clients on the introduction of Additive Manufacturing. This is achieved by a specialized training program, the identification and development of Additive Manufacturing parts, as well as the implementation and qualification of internal and external machine capacity. The company is based in Hamburg, Germany.

Contact

Ampower GmbH & Co. KG

Matthias Schmidt-Lehr

Tel. +49 159 04209421

E-Mail: [email protected]